Hot tsoma galvanizing (karfe tube) m

Ciyarwa → pickling, wanki → sauran ƙarfi → bushewa → zafi tsoma galvanizing → ciki da waje busa → mirgina lakabin, marking → passivation → dubawa → marufi.

Ma'aikacin lodi zai duba yanayin kayan aiki:

1. Bangaren waje na bututun karfe ba zai kasance mai mannewa da mai ba (musamman tabon mai kamar fentin mai hadewar kwalta), in ba haka ba za a haifar da adadi mai yawa na samfuran da ba su cancanta ba.

2. Dole ne a daidaita bututun ƙarfe bayan samarwa don kawar da damuwa na ciki na bututun ƙarfe.

3, da karfe tube surface m lalata ba za a iya galvanized, in ba haka ba da yawa hydrochloric acid za a vata.

- Ba a yarda da lankwasawa ta wucin gadi a cikin tafiyar da bututun ƙarfe ba.

5. Don bututun ƙarfe na galvanized mai zafi mai zafi, ba a ba da izinin liƙa alamomi akan bangon ciki da na waje na bututun ƙarfe don guje wa zubar da ruwa.

1. Zabar bututun karfe:

1) Dole ne ma'aikatan da ke aikin zaɓe su sanya kayan kariya daga aiki kafin aiki, su bincika a hankali ko akwai wurin aikin da ba shi da shinge kuma ko majajjawar ba ta da kyau, sannan za a iya aiwatar da aikin bayan tabbatarwa.

2) Hydrochloric acid ana amfani da shi ne wajen tsinke, kuma ana shirya hydrochloric acid da ruwa.Abubuwan da ke cikin hydrochloric acid shine 18-20%, wanda ya fi dacewa.

3) Fahimtar adadin acid, zafin jiki da kuma yawan bututun da ke cikin tanki kafin a girka.

4) Lokacin ɗaga bututu, slings biyu ya kamata su kasance kusan mita 1.3 daga ƙarshen, don guje wa lanƙwasa bututun ƙarfe da haifar da zubewa a cikin bututun galvanized; a karkatar da 15°, ta yadda za a fara runtse ƙarshen bututun, don hana feshin acid daga cutar da mutane.

5) Kowane pickling na karfe bututu kamata a cikin nauyi na 2 ~ 5 tons da kuma lokacin 5 ~ 15 minutes.

6) Bututun ƙarfe ya kamata ya girgiza akai-akai yayin pickling.A cikin rawar jiki, yakamata a sanya bututun ƙarfe a kan dutsen da ke kwance na tankin acid, sannan a sake fara majajjawa a gefe guda sau 3, sannan a sake kunna majajjawa sau 3. , sa'an nan kuma daga baya bayan maimaita sau biyu; Vibration tashi Angle bai fi 15 ° ba.

7) Lokacin da tankin acid ya yi zafi, gyara bututun tururi da ƙarfi kafin buɗe bawul ɗin tururi.

8) Lokacin da crane crane ya shiga ko ya fita daga tankin acid, kada ya yi karo da bangon tankin don hana lalacewar tankin acid.

9) Manyan abubuwan da ke haifar da tsinkewar bututun ƙarfe:

(1) Dole ne a bincika bututun ƙarfe sosai lokacin ciyarwa, kuma ba za a saka bututun ƙarfe da bai cancanta ba a cikin tsinke.

(2) Ba a sarrafa bututun ƙarfe a hankali lokacin da yake girgiza.

(3) Rashin isasshen lokacin pickling da abun ciki na hydrochloric acid.

10) Manyan abubuwan da ke haifar da tsinken bututun ƙarfe:

(1) Yawan sinadarin hydroelectric acid.

(2)Lokacin karba ya yi tsayi da yawa.

11) Bayan an datse, sai a duba ko saman bututun karfe yana da santsi, ko akwai ragowar sikelin karfe da kuma ko saman bututun ya gurbata da sikelin mai.

2. Wankan ruwa na bututun karfe:

1) Wanke ruwa na bututun ƙarfe ya kamata a gudanar da shi a cikin tankin ruwa mai gudana.A jika duk bututun ƙarfe a cikin ruwa lokacin wankewa, shakata da majajjawa mai tsini sannan a cire kuma a kashe har sau uku zuwa huɗu.

2) Bayan wankewa, ruwan da ke cikin bututun ƙarfe ya kamata a sarrafa shi kuma a bi da shi tare da sauran ƙarfi da wuri-wuri don hana iskar oxygen da bututun ƙarfe.

3) Abubuwan da ke cikin ƙarfe da gishiri a cikin ruwa mai tsabta ba za su wuce misali ba, kuma ba za a sami wasu nau'i ba.Za a kiyaye shi da tsabta kuma a bayyane.

4) Lokacin tsaftace bututun, an haramtawa masu aiki su bi ta tankin tsinke don hana zamewa ko fadawa cikin tankin don cutar da mutane.1.Lokacin da bututun ƙarfe ya shiga cikin tanki mai ƙarfi, sassauta majajjawa ta yadda bututun ƙarfe ya nutsar a cikin sauran ƙarfi gaba ɗaya.Ba a yarda da saman bututun ƙarfe don fallasa ƙasa mai ƙarfi. Har sai ƙarshen bututun ƙarfe biyu ba su da kumfa, za a ɗaga gefe ɗaya na bututun ƙarfe sama da ƙasa don girgiza, kuma za a ɗaga bututun ƙarfe zuwa sarrafa kaushi mai tsabta sannan ya shiga cikin benci mai bushewa.

2. Ƙaƙwalwar Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarfe ba zai zama mafi girma fiye da 15 ° a cikin tsarin maganin maganin ba.

3, da karfe tube a cikin ƙarfi immersion lokaci na 60 ~ 120 seconds, da mayar tube nutsewa 3 ~ 5 minutes, da mayar tube nutsewa 5 ~ 10 minutes.

4. zafin jiki mai narkewa: Ci gaba da tsabtace sauran ƙarfi a cikin zafin jiki.

5. Bayan maganin kaushi, kada ku tsaya ga sauran datti, kada ku jika, sanya shi a cikin tebur na bushewa don daidaitawa; Ba a yarda mutane su taka bututun karfe wanda aka sanya a kan benci na bushewa.Idan dole ne a taka, ƙafa biyu dole ne a rufe su da ammonium chloride kafin yin aiki akan bututu.1.Bayan m sauran ƙarfi jiyya, sanya karfe bututu a kan bushewa da kuma karba dandali, da kuma sanya karfe tube a gaban gaban tutiya tukunya da kuma gaban gaban na biyu Magnetic abin nadi zuwa square a dama kwana;A mafi lankwasa bututu da aka sanya. a baya ko a daidaita kuma a sanya shi a kan tarkon karɓa.

2. Babban aikin bushewa KANG shine bushe ruwan da ke saman bututun karfe.A daya bangaren kuma, shi ne a kara yawan zafin jikin bututun karfe da kansa, da hana zubewar zinc daga cutar da mutane, da kuma kawar da karfin zafin da ke cikin tukunyar zinc, ta yadda za a hanzarta samuwar sinadarin zinc-ferroalloy.

3. The bushewa zafin jiki na kang ne 80 ℃ ~ 180 ℃, da kuma bushewa lokaci na karfe bututu ne 3 ~ 7 minutes.Hakanan za'a iya sarrafa zafin jiki na bushewa bisa ga ƙayyadaddun ƙayyadaddun bayanai da kauri na bango na bututun ƙarfe. Masu bushewa yakamata su duba matakin bushewa na bututun ƙarfe a kowane lokaci don hana ƙarancin lokaci a cikin ruwan tutiya fantsama zinc rauni; Lokacin bushewa, yi. ba wuce zafin jiki ba, don hana sauran ƙarfi yin burodi coke.The zafi-tsoma galvanized karfe bututu rungumi dabi'ar inji bugun kira a, latsa ƙasa, spiraling, ja da kuma dagawa a cikin hanyar da cikakken tsoma Semi-atomatik galvanized karfe bututu don kammala. da zafi- tsoma galvanizing tsari.

1. Gudanar da sigogi na tsari: Ya kamata a sarrafa zafin jiki na maganin zinc tsakanin 440-460 ℃; Zinc dipping lokaci ya kamata a sarrafa tsakanin 30-60 seconds; Aluminium abun ciki (Likitan tutiya mai dauke da aluminum 0.01-0.02%)

2. Zinc ingot yakamata ya zama zN0-3 zinc ingot tare da daidaitattun ƙasa.

3. Kulawa da sarrafa ingantaccen aiki na cirewa da latsawa da kuma cire kayan ɗagawa akai-akai, ƙarfafa lubrication na Silinda, daidaita tsayi da kusurwar mai rarraba bututu mai galvanizing da kyau, da daidaita kayan aiki zuwa yanayin mafi kyau.

4. Sanya madaidaicin kusanci daidai; Thermocouple layin da mita da za a yi amfani da su a cikin samfurin iri ɗaya, in ba haka ba, kuskuren zafin jiki yana da girma, hannun rigar kariya na thermocouple, sau da yawa duba da maye gurbin.

5. Mai aiki na tashar aiki dole ne ya daidaita saurin da hannu bisa ga yanayin aiki na kayan aiki a gaban tanderun da kuma umarnin motsi don hana bututu.

6. Yi preheat kayan aikin da ma'aikatan tanderu ke amfani da su kafin yin amfani da su don hana zubewar zinc da rauni, akai-akai bincika ko bututun ƙarfe ya faɗi cikin tukunya, idan akwai, don sharewa cikin lokaci; Don daidaita kayan aikin kar a tsaya bututu, don tabbatar da amincin kayan aiki.

7. Lokacin ƙara zinc a cikin tukunyar zinc, abubuwan da ke cikin zinc ya kamata a fara zafi da farko.Kada a taɓa ƙyale a ƙara dauren zinc, bai wuce guda biyar na zinc a lokaci ɗaya ba.An hana a jefa baƙin ƙarfe a cikin ruwan zinc don hana yawancin zinc slag.

8, a lokacin narkewar zinc a hankali a rika dumama, kar a kona wuta, in ba haka ba, zai lalata rayuwar tukunyar galvanized, sannan kuma ana yawan juyar da tururin zinc da yawa, idan aka shakar da shi da yawa, wannan iskar gas mai cutarwa yana haifar da wani yanayi mai suna “Fundry fever. "A yayin aikin narkewar zinc, da zarar zinc yana da zafi mai yawa, kada a taɓa shingen zinc da hannu, don guje wa konewa, ya kamata a yi amfani da kayan aikin da suka dace don taɓa shi.

9, a kai a kai share tutiya ruwa surface na tutiya ash.Lokacin scraping da ash ya kamata a hankali a kan saman tutiya ruwa tare da scraping farantin scraping swab, ba zai iya motsa da yawa, don gudun da tutiya ash taso, da scraping farantin kada ya zama. tsoma zinc ko fita daga cikin bututu lokacin da bututun ƙarfe ya tuntuɓi, don kada ya jujjuya faruwar haɗarin sirri ko haɗarin kayan aiki.

10. Tushen zinc da ke ƙasa a gaban tanderun, karyewar zinc, zinc da ake fitar da su lokacin galvanizing, da bututun ƙarfe na zinc da ke gudana zuwa waje ya kamata a dawo dasu a kowane lokaci don rage zafin tukunyar zinc.

11. Lokacin da aka ƙara ingots na aluminum zuwa saman tutiya na ruwa, dole ne a motsa shi sau da yawa kafin da kuma bayan don tabbatar da abun ciki na aluminum a kan saman tutiya na ruwa.

12. Domin saukaka zubar ruwa da fitar da sinadarin zinc, sai a sanya ton 20 na gubar a cikin tukunyar zinc.

13, slag dregs don preheat da dregs, zinc slag da za a raba zuwa manyan da kananan tubalan ajiya, zazzabi na dregs ya kamata a sarrafa a 455 ℃ a sama, lilo slag inji dole ne a yi amfani da musamman kayan aiki, nesa da tukwane 1 mita. ƙafafu don tsayawa a cikin mai siffa t.

14, zafi tsoma galvanizing tsari bukatun more rigorous, don haka a cikin zafi tsoma galvanizing samar tsari, dole ne bushe cikakken tashar, wato, a cikin naúrar lokaci tushen lambar ko tonnage more, da ƙananan kudin, kuma mataimakin versa mafi girma.1.Bayan an gabatar da bututun da aka yi amfani da shi a gaba, ana amfani da tebur na maganadisu don fitar da bututun galvanized, kuma jujjuyawar injin ɗin ba ta da sauri sosai, ta yadda zinc ɗin ke gudana da tsabta kafin busa ciki.

2. Matsakaicin zoben busa na waje ya kamata ya kasance daidai da abin nadi na maganadisu a kusurwoyi madaidaici, kuma tsayin tsayi da matsakaici ya kamata su kasance tabbatacce don tabbatar da cewa bututun galvanized ya ratsa tsakiyar zoben iska.

3. Lokacin shigar da abin nadi na maganadisu, masu maganadisu na maganadisu guda biyar dole ne su kasance a kan layin tsakiya don tabbatar da daidaiton layin tutiya na bututun galvanized da aka hura a waje.

4. Za a yi busa na waje tare da matsa lamba, zai fi dacewa a sama da 70 ℃, a ƙarƙashin matsin lamba na 0.2-0.4mpa.

5. Za a daidaita karfin iska a ƙarƙashin yanayi masu zuwa:

(1) Tushen tutiya a saman farfajiyar bututun galvanized ya yi kauri sosai.

(2) Fuskokin zinc Layer ya zama duhu bayan busa waje.

(3) Bayan busawa na waje, saman tudun zinc yana manne da sundries kuma ana cire abubuwa marasa tsabta.Ya kamata a daidaita ƙarar iska.

6. Sauya zoben iska na ƙayyadaddun ƙayyadaddun daidai da ƙayyadaddun bututun ƙarfe na galvanized.Ba za a iya maye gurbin zoben iska da wasu ƙayyadaddun bayanai ba.

7. An haramta wuce galvanized bututu a karkashin yanayin da babu iska, don haka kamar yadda ba ya haifar da blockage na iska rami da kuma rinjayar da ingancin waje hurawa.

8. Koyaushe bincika ko ciki na zoben busa na waje yana da tsabta, ko akwai rataye zinc, ko saman waje na bututun galvanized yana da santsi kuma ko akwai karce; , idan an haɗa shi da zinc don tsaftacewa a cikin lokaci.

9. Tunda babu wani abin nadi na maganadisu kuma tudun zinc ɗin bai da ƙarfi, saman tudun zinc ɗin shine mafi kusantar zazzagewa, don haka saurin babban abin nadi ya kamata yayi daidai da na abin nadi.1.Ana aika bututu mai zafi mai zafi zuwa gefen mai busa na ciki ta na'urar gubar, kuma ana amfani da maɓallin kusanci don kammala motsi na kwance, danna saukar da busawa na ciki, ɗaga kan matsa lamba, da motsa galvanized mai zafi tsoma galvanized. bututu a cikin kwandon sanyaya.

2. Bututu mai zafi shine mafi kusantar da za'a iya zazzage shi akan teburin abin nadi na gubar.Babban dalili shi ne, zinc ba ta da ƙarfi sosai yayin aikin bututun.

3. Ana amfani da tururi don busawa na ciki, kuma matsa lamba na ciki shine 0.4-1.0mpa; Dole ne ya zama santsi.

4, galvanized bututu a cikin sarkar don kula da wani karkatar Angle, sabõda haka, sanyaya ruwa net.

5. Wurin aiki na busa na ciki yana samuwa a cikin wani wuri mai zurfi tare da ƙananan filin aiki, don haka dole ne a yi aiki da shi a hankali don hana raunin rauni, fadowa da lankwasawa; Ƙaddamar da hana wani ɓangare na jiki, hulɗar kai tsaye tare da babban zafin jiki na galvanized bututu, don gujewa rauni.

6. Kula da ko ƙafafunku sun tsaya tsayin daka kuma akwai wasu matsaloli don hana ku fadawa cikin nutsewa; Yana da sauƙin barin sarkar da ke gudana a kan nutse, don hana raunin tube mai tashi. Ma'ana: Lokacin da sassan ke buƙatar adanawa. kuma ana jigilar su na dogon lokaci, ya kamata a aiwatar da wuce gona da iri a tsakanin sassan don hana lalata a cikin tsarin ajiya da sufuri.Sau da yawa samfuran lalata ana kiransu farin tsatsa.Hanyoyin wucewa na yau da kullun sun haɗa da chromate da phosphate.

1. Hanyar wucewa: Ana amfani da bututu mai zafi mai zafi don fesa maganin wucewa kai tsaye a kan titin jirgin sama, kuma ana goge maganin a nesa na mita daya daga wurin fesa ta wukar tururi.Yi hankali don busa maganin wucewa.

2. Shafa tare da iska mai matsawa don busa ruwa a saman saman bututun karfe kuma sanya suturar ta zama daidai.Ta hanyar daidaita matsa lamba don daidaita kauri na rufin, kada a haɗe beads da yawa a saman tudun zinc. 1.Rolling mark da roller:

1) Lokacin da na'urar yin alama ke aiki, kar a taɓa abin nadi tare da hannunka don hana latsa hannu; An hana shi wuce bututu biyu ta na'urar yin alama don hana lalacewar rubutun latsawa.

2) A yayin aiki na bututun galvanized a cikin tebur mai ɗaukar nauyi, na'ura mai alamar za ta canza bayanin kula bisa ga ƙayyadaddun bayanai daban-daban, kuma za a daidaita tsayin ƙafafun latsa da zarar an canza ƙayyadaddun bayanai, kuma ana ƙara mai akai-akai.

3) Ya kamata a rika duba zoben roba na na'ura mai alamar birgima a akai-akai kuma a maye gurbinsu cikin lokaci idan an sami fashewa.

4) Za a danna motar roba a kan tsakiyar layin karfe na karfe, kuma za a gyara ƙugiya na sama da na ƙasa tare da matsi mai kyau.

5) Lokacin buga zoben tambarin, mutane biyu su yi birgima a lokaci guda.Ya kamata a ƙara tawada akai-akai don mirgina bututun ƙarfe da ji, amma tawada ba shi da sauƙi ya yi yawa.

2. Marufi:

1) Baler yana amfani da iskar gas compressor, kuma matsa lamba shine 0.4-0.8mpa.An hana ka taɓa sassan motsi na baler da hannunka don guje wa cutar da hannunka a ƙarƙashin yanayin aiki na baler.

2) Lokacin tattara kaya, da farko sanya ƙullun a kan bel ɗin tattarawa, sannan sanya bel ɗin tattarawa a kusa da bututun ƙarfe kuma saka ɗayan ƙarshen a cikin ɗigon.Sa'an nan kuma danna na'urar baling a kan bel ɗin tattarawa kuma buɗe bawul ɗin iska na injin baling don ɗaukar kaya da dannawa.Ana buƙatar bel ɗin tattarawa ya zama 100mm nesa da ƙarshen, 300mm nesa da sashi na biyu, kuma 400mm nesa da ƙarshen alamar mashaya shuɗi.

3) Zaɓi madaidaicin marufi na ƙayyadaddun ƙayyadaddun ƙayyadaddun bututun galvanized, sanya bututun galvanized a cikin siffar hexagonal kuma sanya ƙarshen ɗaya daidai.

4) Da zarar saman waje na bututun ƙarfe yana haifar da gurɓatacce, tsaftace shi da yashin auduga mai tsafta kafin tarawa.Idan yanayi ya ba da izini, ya kamata a sarrafa ruwan da ke cikin ƙaramin bututu kuma a tsaftace shi; Kada ka yarda kowa ya taka bututu da ƙafarsa, don kula da bayyanar ingancin bututun galvanized.

Tianjin Rainbow Karfe Group ƙwararrun masana'anta ne na ƙarfe a China.

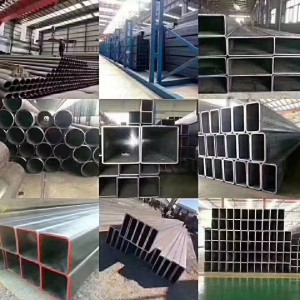

Samfurin da za mu iya kerawa kamar haka:

Babban Kayan Samfurin Mu:

1. Karfe Bututu(Zagaye / Square/ Siffa ta Musamman/SSAW)

2. Bututun Wutar Lantarki(EMT/IMC/RMC/BS4568-1970/BS31-1940)

3. Sashin Karfe Mai Sanyi(C/Z/U/ M)

4. Karfe Angle da Beam(V Angle Bar / H Beam / U Beam)

5. Karfe Scafolding Prop

6. Tsarin Karfe(Ayyukan Frame)

7. Daidaitaccen Tsarin Kan Karfe(yanke, mikewa, lallasa, latsa, zafi mirgina, sanyi mirgina, stamping, hakowa, waldi, da dai sauransu bisa ga abokin ciniki ta bukata)

8. Karfe Tower

9. Tsarin Hawan Rana

Amfanin Kamfaninmu:

1.Farashin:Kamfaninmu yana cikin Tianjin China.Shekaru da yawa, Tianjin ta kasance cibiyar masana'antar karafa kuma mafi girman tushen samar da bututun karfe a kasar Sin.Sarkar masana'antu na samfuran ƙarfe da ƙarfe sun cika;Yana da babban kayan aiki da albarkatun aiki anan.Don haka nau'ikan bututun ƙarfe da aka yi a nan ya cika sosai, ingancin yana da kyau, farashin yana da fa'ida sosai.A matsayin kamfani na rukuni, masana'antun mu guda huɗu za su iya samun mafi kyawun farashi na albarkatun ƙasa saboda yawan adadin siyayyar nau'ikan kayan.Farashin kayayyakin fitarwa duk farashin intro-group ne, don haka muna da fa'idar farashin fiye da sauran masu fitarwa masu zaman kansu.

2.Sufuri:Makarantun mu suna da nisan kilomita 70 daga tashar Tianjin, wacce ita ce tashar jiragen ruwa mafi girma a arewacin kasar Sin, tare da jigilar jiragen ruwa zuwa tashoshin jiragen ruwa sama da 300 a cikin kasashe 170.Kamfaninmu ne kawai Yana da matukar dacewa kuma yana adana lokaci da farashi a sufuri.

3.Sabis tasha ɗaya:A matsayinmu na kamfani, muna da injina guda huɗu tare da ɗakunan ajiya na zamani & kayan sarrafa kayan aiki, za mu iya ba ku samfuran ƙarfe da yawa: zafi da sanyi da aka kafa, gami da mashaya iri-iri iri-iri, samfuran tsari da tubular.Muna da duk kayan aikin ƙarfe na gida, kasuwanci da masana'antu da sabis da zaku iya buƙata.Don haka idan ka saya daga gare mu, abin da za mu iya bayarwa shi ne sabis na samfurin karfe na tsayawa ɗaya.Yana adana lokaci mai yawa na siyan ku da farashin samowa.

4. Ƙarfin samfur da bayarwa:

Muna da babban iya aiki, da kuma fitarwa fiye da 3500 ton a mako guda (kusan 150 20 GP kwantena) , Za mu iya isar da kaya A cikin 20-30 kwanaki bayan samun T / T ajiya ko L / C.Don umarni na gaggawa na musamman, za mu iya rage lokacin jagora zuwa kwanaki 10.

5. Kerarre bisa ga ma'auni daban-daban, Haɗu da ma'auni daban-daban:

Tun da an fitar da samfuranmu zuwa ƙasashe da yankuna daban-daban kamar Turai, Amurka, Ostiraliya, Afirka, Asiya da sauransu, samfuranmu na iya biyan buƙatun ma'auni na ƙasa daban-daban.Idan kuna da buƙatu na musamman, kawai gaya mana, za mu iya samar muku da samfuran da aka keɓance, ba kawai biyan buƙatun ku masu inganci ba, amma har ma ku adana kuɗi mai yawa.

ƙwararrun ma'aikatanmu da ƙwararrun ma'aikatan koyaushe a shirye suke don amsa tambayoyinku game da samfuranmu da ayyukanmu.

Tianjin Rainbow Steel Group Co., Ltd.

Lambar waya: 0086-22-59591037

Fax: 0086-22-59591027

Wayar hannu: 0086-13163118004

Imel:tina@rainbowsteel.cn

Saukewa: 547126390

Yanar Gizo:www.rainbowsteel.cn

Yanar Gizo:www.tjrainbowsteel.com

Lokacin aikawa: Agusta-17-2020