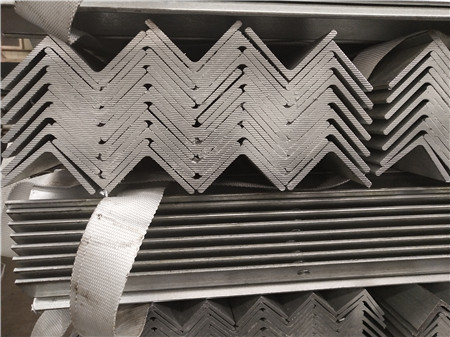

Karfe Ang

Bayanin:

1. Karancin jiyya: Farashi mai ɗimbin ruwan zafi yana da girma fiye da na sauran kayan kwalliya.

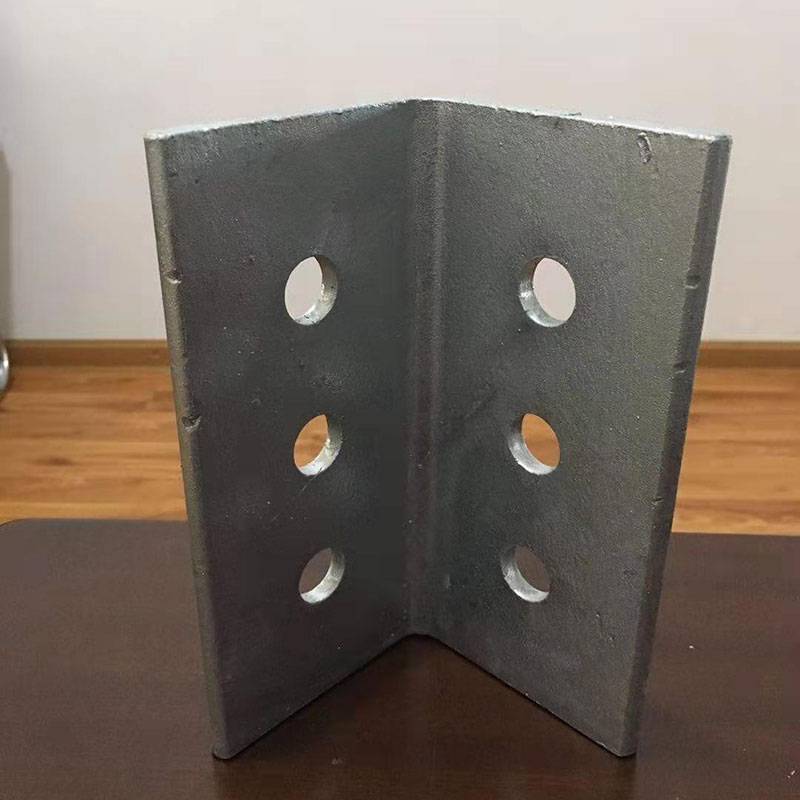

2. M: ƙarfe mai ɗumi-ruwa mai ƙarfi mai ɗumi yana da halayen shimfiɗaɗɗar dusar ƙuraje, maɓallin zinc mai ɗorawa, babu yayyo, babu tsalle-tsalle, ƙaƙƙarfan ƙarfi da juriya mai ƙarfi. A cikin kewayen kewayen birni, ana iya kiyaye madaidaicin kauri irin na tsatsauran tsatsa mai-tsawan shekaru fiye da 50 ba tare da gyara ba; A cikin birane ko bakin teku, daidaitaccen lokacin farin ciki mai tsafta wanda zai iya tsayawa shekaru 20 ana iya kiyaye shi. Ba ya buƙatar gyara.

3. Dogaro mai kyau: Fuskar galvanized shine ƙarfe na ƙarfe tare da ƙarfe kuma ya zama wani ɓangare na farfajiyar ƙarfe, don haka ofarfin rufin ya fi aminci.

4. Murfin yana da ƙarfi mai ƙarfi: maɓuɓɓugan jujjuyawar ƙasa yana ba da tsarin ƙarfe na musamman, wanda zai iya tsayayya da lalacewar inzali yayin sufuri da amfani.

5. Cikakken kariya: Kowane sashi na ɓoyayyen sashin da za a iya shimfidawa, ko da a cikin ɓacin rai, kusurwa mai kaifi da wurin ɓoye ana iya samun cikakken kariya;

6. Adana lokaci da tanadin aiki: aiwatar da tsarin ya fi sauri fiye da sauran hanyoyin ɗaukar hoto, kuma zai iya guje wa lokacin da ake buƙata zanen a wurin bayan an gama sanyawa.

Kayan aiki

Q235 Q345 Q420 (low carbon steel) Abubuwan sunadarai

C: 0.06-0.12 Mn: 0.25-0.50 Si <= 0.30 P <= 0.45 Karfin Tensile: 315-435 (Mpa)

Harafin Murfin 3-20mm

Fasahar zafi tayi birgima

Kusurwa mai ban tsoro

Girman girma 20 * 20-250 * 250

Tsawon 1-12m

Samun haƙuri mai kauri ƙuri'a: +/- 0.02mm Haƙurin Layi: +/- 10mm

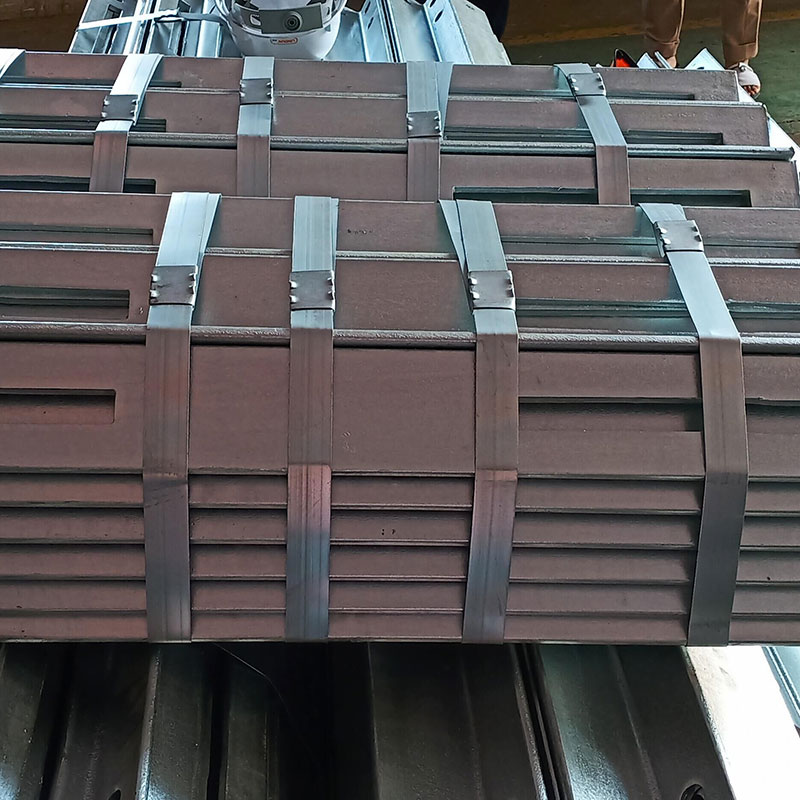

Fakitin 1.Daure 2.Akwai a waje 3.Da Kullum 4.Askan abokin ciniki

Lokaci na Isarwa A tsakanin kwanaki 20, ASAPA yawan adadin

| Musammantawa: | ? 20 * 20-250 * 250 |

| Lokacin farin ciki: | ? 2MM-20MM |

| tsawon: | ? 6M 9M 12M (yankan don biyan buƙatarku) |

| Kayan aiki: | ? karfe ƙarfe |

| Surface jiyya: | ? Baki da Galvanized |

| Fasali: | ? Q195, Q235, Q345 (daidaitaccen Sinanci) |

| Zinc ውፍረት: | ? 35 ~ 85 micron |

| Tsarin aiki don tunani: | ? Chingorawa |

Aikace-aikace:

?An yi amfani dashi ko'ina a cikin tsarin gini da injiniya iri-iri. Bangon labule, sito, kore, ect.